Introduction to Powder Coating Gun Systems

A Powder Coating Gun System is an integrated setup designed for high-efficiency, large-scale application of electrostatic powder coatings across industries. These systems combine advanced spray guns, automated controls, powder feeders, and recovery modules to deliver precise, uniform finishes on metal substrates. Ideal for automotive, aerospace, and appliance manufacturing, they eliminate solvents, reduce waste, and ensure compliance with environmental regulations. Prices vary widely, from 5,000forbasicmanualsystemsto100,000+ for fully automated lines with robotic arms. Key features include adjustable voltage (30–100 kV), IoT-enabled monitoring, and rapid color-change capabilities. By optimizing powder coating gun system efficiency, businesses achieve faster production cycles and superior durability compared to liquid coatings.

1. Components of a Powder Coating Gun System

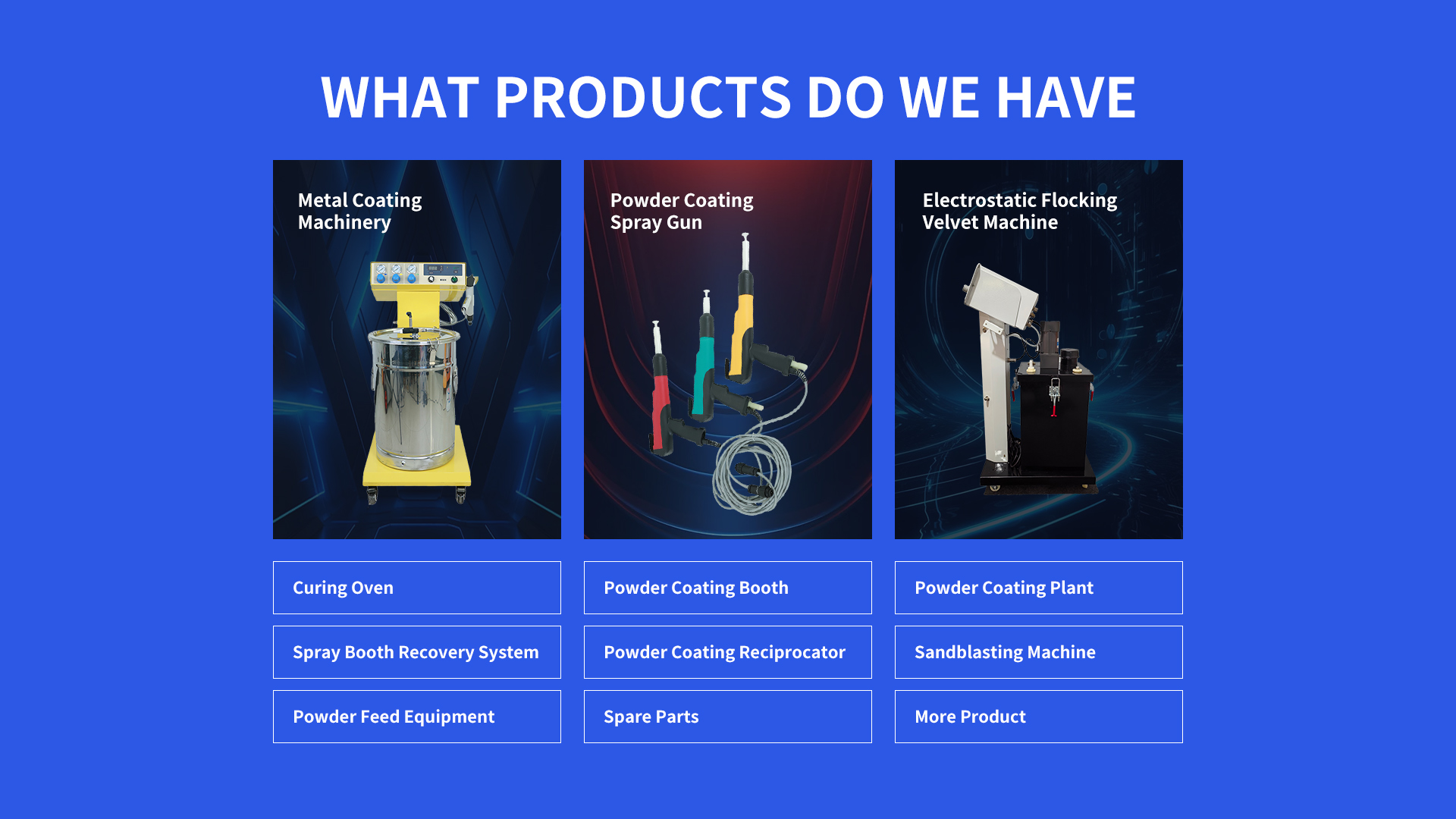

A complete Powder Coating Gun System typically includes:

Spray Gun: Manual, automatic, or robotic models with electrostatic charging.

Powder Delivery System: Pumps, hoses, and fluidized hoppers for consistent flow.

Control Unit: Adjusts voltage, airflow, and spray patterns via touchscreen interfaces.

Recovery Module: Cyclones or filters to reclaim oversprayed powder (up to 95% reuse).

Curing Oven: Infrared or convection ovens to melt and cure coatings.

Advanced systems integrate automated powder coating systems with real-time diagnostics.

2. Applications of Powder Coating Gun Systems

These Powder Coating Gun Systems excel in:

Automotive Production Lines: Coating chassis, wheels, and engine parts at high speeds.

Consumer Electronics: Applying scratch-resistant finishes to appliances and gadgets.

Heavy Machinery: Protecting agricultural and construction equipment from corrosion.

Architectural Projects: Durable coatings for steel beams, railings, and façades.

They’re indispensable in high-volume manufacturing and precision coating tasks.

3. Design Considerations for Powder Coating Gun Systems

Critical design factors include:

Scalability: Modular designs to expand from semi-automatic to full automation.

Energy Efficiency: Low-consumption pumps and recovery systems to cut costs.

Safety Compliance: Grounding mechanisms, explosion-proof components, and ventilation.

Ease of Maintenance: Quick-access panels and self-cleaning functions.

Adhering to industrial powder coating safety standards minimizes downtime and hazards.

4. How to Choose a Powder Coating Gun System

Evaluate based on:

Production Volume: Robotic systems for 24/7 operations; manual units for small batches.

Powder Type: Compatibility with epoxy, polyurethane, or specialty powders.

Budget: Entry-level systems start at 5,000;premiumautomatedsetupsexceed50,000.

Brand Support: Prioritize suppliers offering powder coating system maintenance training and warranties.

5. Powder Coating Gun System Q&A

Q: How to optimize powder recovery rates?

A: Use high-efficiency cyclones and ensure proper powder coating system calibration.

Q: Can systems handle multiple colors?

A: Yes, with quick-color-change modules to reduce cross-contamination.

Q: What causes system clogging?

A: Humidity, poor powder flow, or incorrect settings—store powder in dry conditions.

Q: Are robotic systems worth the investment?

A: For large-scale production, automated powder coating systems boost speed and consistency.

Q: How to ensure operator safety?

A: Regular grounding checks, PPE, and adherence to industrial coating safety protocols.

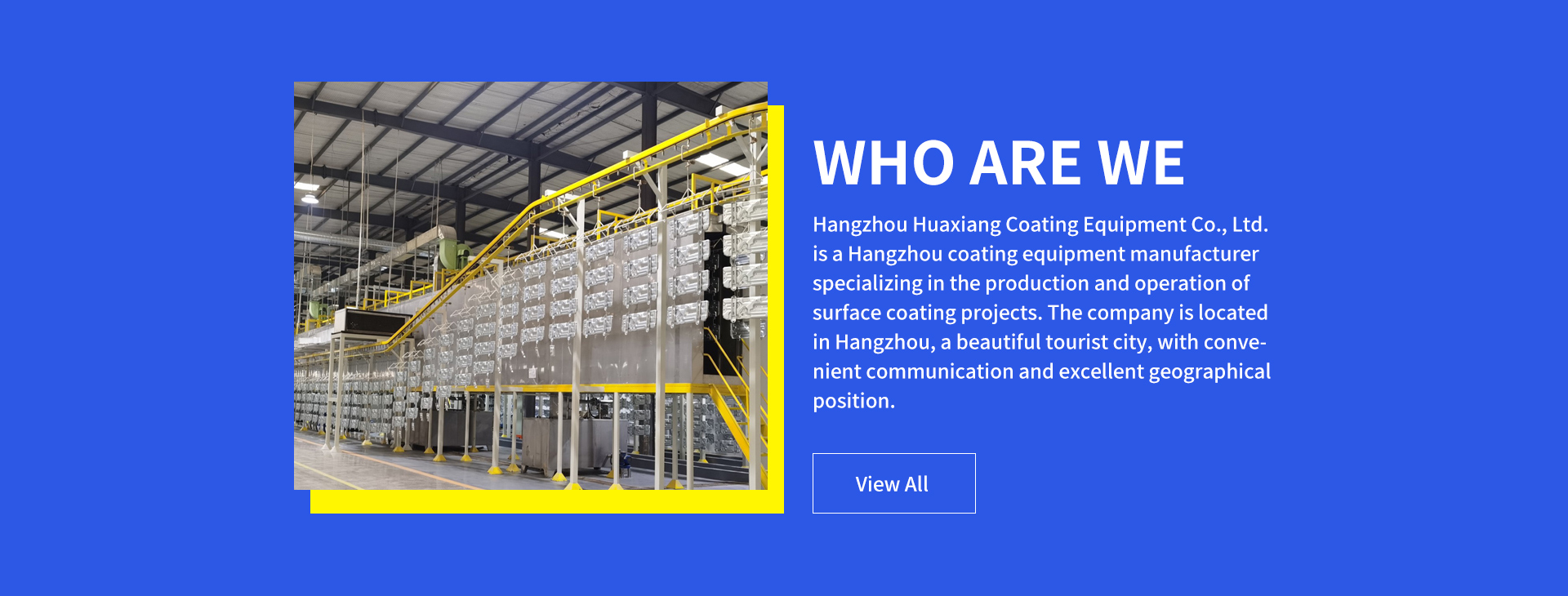

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com